CW系列单向阀

结构特点STRUCTURAL FEATURES:

全焊接结构提供牢固可靠的流体系统控制能力 Fully welded structure provides solid and reliable fluid system control capability

当压差不到2PSIG(0.14bar)时,阀门即可产生正向流动 When the pressure difference is less than 2PSIG (0.14bar), the valve can generate forward flow

当背压5~10PSIG(0.34~0.69bar)时,阀即可关闭 When the back pressure is 5-10PSIG (0.34-0.69bar), the valve can be closed

合金弹性元件提供持久弹性,提高阀门使用寿命 Alloy elastic components provide long-lasting elasticity and improve valve service life

技术参数TECHNICAL PARAMETERS:

|

接口尺寸 Connection |

1/4″ |

3/8″ |

1/2″ |

|

流量系数Cv Flow Capacity |

0.55 |

0.7 |

0.7 |

|

最大工作压力 Maximum Pressure |

3000PSIG (206bar) |

||

|

正向开起压力 Opening Pressure |

<2PSIG(0.14bar) |

||

|

反向密封压力 Reverse Sealing Pressure |

5~10PSIG (0.34~0.69bar) |

||

|

工作温度 Operating Temperature |

-10~80℃(-23~176ºF) |

||

|

外部泄露率 Outboard Leak Rate |

≤1x10(-9次方) atm.cc/sec He |

||

|

流道面粗糙度 Internal Surface Finish |

BA级Ra0.4,HP级Ra0.25,UHP级Ra0.13 BA Class Ra0.4,HP Class Ra0.25,UHP Class Ra0.13, |

||

|

压力设计强度 Design Proof Pressure |

1.5 of maximum rated |

||

|

清洗标准 Cleaning Standards |

BA级EC-01,HP级EC-02,UHP级EC-03 BA Class EC-01,HP Class EC-02,UHP Class EC-03 |

||

流体接触件材料MEDIA CONTACT MATERIALS:

①入口阀体(Inlet Valve) 316L / 316L VAR

②密封圈(Sealing Ring)FKM

③压环(Pressure Ring)316L / 316L VAR

④弹簧 (Spring) X750/Hastelloy C-22

⑤提升阀座(Support Base) 316L / 316L VAR

⑥ 挡圈(Retaining Ring) 316L / 316L VAR

⑦出口阀体(Outlet Valve ) 316L / 316L VAR

* EP级:金属零件做EP处理/Metal parts do Electrolytic polishing

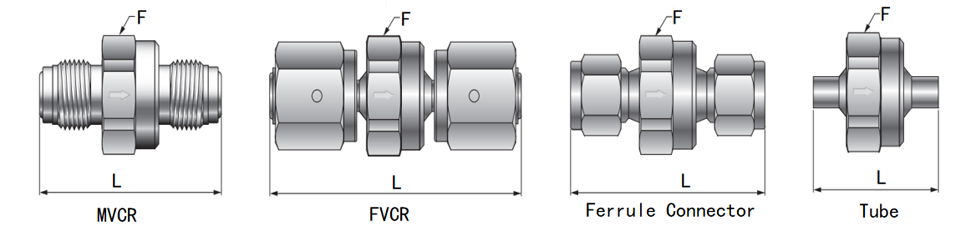

尺寸与连接方式CONNECTIONS:

|

接口类型 CONNECT MODE |

接口尺寸 SIZE |

基本型号 BASIC MODEL |

尺寸/mm |

|

|

L |

F |

|||

|

Ferrule Connector |

1/4 “ |

-CW-FL4-0- |

49.8 |

22.23 |

|

MVCR |

1/4 ” |

-CW-MR4-0- |

45.8 |

22.23 |

|

1/2 “ |

-CW-MR8-0- |

52.3 |

27 |

|

|

FVCR |

1/4 ” |

-CW-FR4-0- |

61.7 |

22.23 |

|

1/2 “ |

-CW-FR8-0- |

61.7 |

27 |

|

|

TUBE |

1/4 ” |

-CW-T4-0- |

31.5 |

22.23 |

|

3/8 “ |

-CW-T6-0- |

31.5 |

22.23 |

|

|

1/2 ” |

-CW-T8-0- |

31.5 |

27 |

|

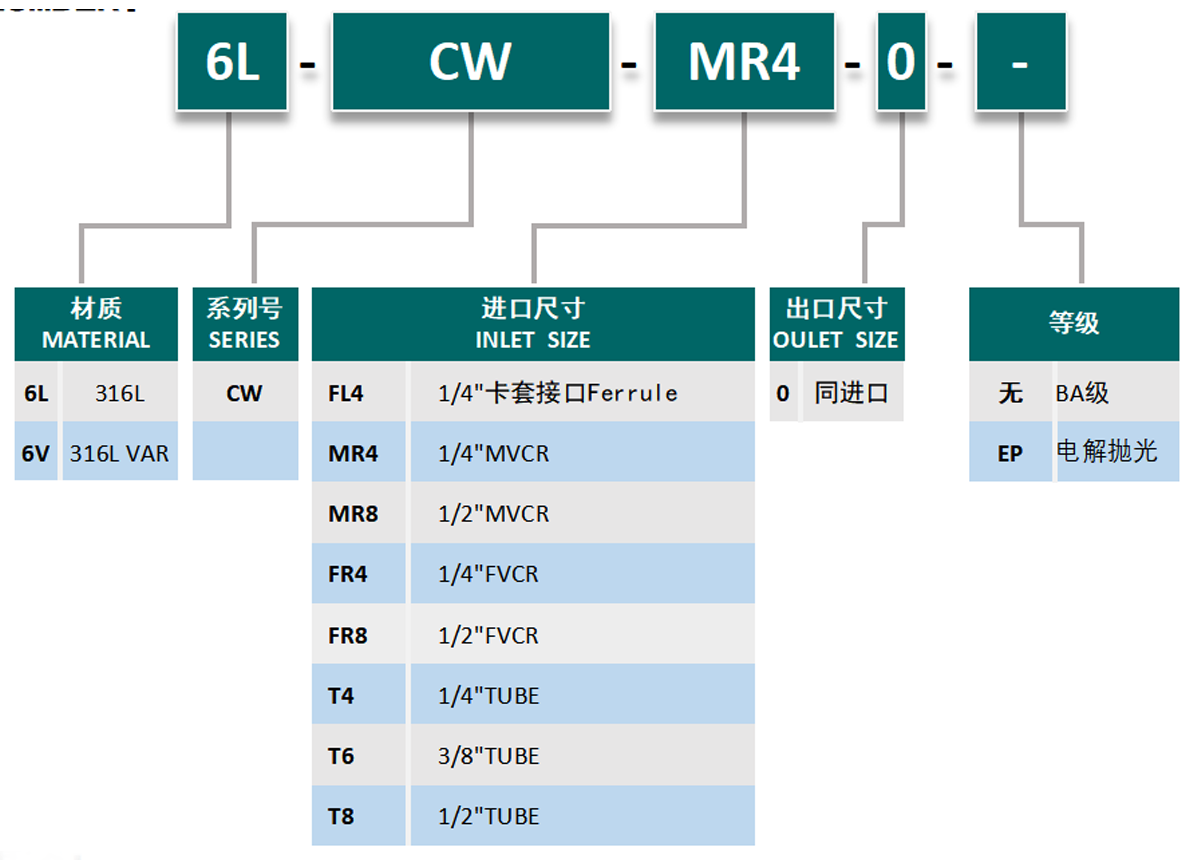

订购选型ORDER NUMBER:

注意事项POINTS FOR ATTENTION:

- 安装前请先阅读说明书,明确安装和使用方法 Please read the manual before installation to clarify the installation and usage methods

- 在洁净环境下打开包装与使用,避免受到污染 Open packaging and use in a clean environment to avoid contamination

- 拆开未使用的产品,需立即重新封装,避免受到污染 Unpacking unused products requires immediate repackaging to avoid contamination